home > news > company news

cycloaliphatic epoxy resins — thermal curing application

|

update: 2020-6-22 |

常用的环氧固化剂花样繁多,固化技术也多种多样 (热固化、微波固化、光固化等),但大多数适于光固化的环氧树脂不一定适于热固化,当然也有光固和热固都行的,但是这样的体系比较少,脂环族环氧树脂就是其中一例。在上一期内容中,我们介绍了脂环族环氧树脂的光固化应用篇。本期我们将重点讲述脂环族环氧树脂的

另一大优势——热固化应用篇。

a wide variety of epoxy curing agents and curing technologies (thermal curing, microwave curing, uv curing, etc.) can be commonly used. most of the uv curable epoxy resins are not suitable for thermal curing. very few epoxy compounds, such as cycloaliphatic epoxy resins, are both uv curable and thermal curable. in the previous article, we introduced the uv curing application of cycloaliphatic epoxy resins. in this article, we will focus on another great advantage of cycloaliphatic epoxy resins —

thermal curing application.

环氧树脂通常作为涂料、复材和胶黏剂等材料的基体,广泛应用于建筑、电子电气、航空航天等领域。一个完整的环氧树脂体系一般由四种成分组成,包括环氧树脂、改性剂、流动性调节剂和其他成分 (颜料、溶剂、消泡剂、流平剂、增粘剂等) 。但实际应用时,不一定要这四种成分都具备,但树脂成分必须包括固化剂,可见固化剂的重要性。

epoxy resin is generally used as a substrate of coatings, composites, adhesives and other materials. it is widely used in construction, electrical and electronic, aerospace and other fields. a complete epoxy resin system is generally composed of four parts, including epoxy resin, modifier, flowability regulator and some others (such as pigment, solvent, defoamer, leveling agent, tackifier, etc.). in fact it is not necessary to have all these four parts, but the resin part must include the very important curing agent.

脂环族环氧树脂的主要热固化方式即酸酐固化。酸酐固化剂常用的为六氢苯酐、甲基四氢苯酐、氯乙酸酐等。它的挥发性小,毒性小,对皮肤的刺激性也小。而且它的使用期长,操作也方便。通常酸酐类固化速度较慢,但固化物刚性好。

the thermal curing agent for cycloaliphatic epoxy resins is mostly anhydride type. commonly used anhydride type curing agent can be hexahydrophthalic anhydride (hhpa), methyl tetrahydrophthalic anhydride (mthpa), chloroacetic anhydride, etc. it is less volatile, less toxic or less irritant to skin. it can be easily operated and used for a long time. generally anhydride curing agent has low curing speed, but the cured material can provide good rigidity.

主要酸酐分类:

1. 顺酐>苯酐>四氢苯酐>甲基四氢苯酐

2. 六氢苯酐>甲基六氢苯酐

3. 甲基纳迪克酸酐

4. 均苯四甲酸二酐

5. 改性酸酐

6. 酸酐分子中负电性取代基则活性增强

main anhydride classification:

1. cis-butenedioic anhydride > o-phthalic anhydride > tetrahydrophthalic anhydride > methyl tetrahydrophthalicanhydride

2. hexahydrophthalic anhydride > methylhexahydrophthalic anhydride

3. methyl-5-norbornene-2,3-dicarboxylicanhydride

4. pyromellitic dianhydride

5. modified anhydride

6. anhydride with electronegative substituent for increased reactivity

脂环族环氧树脂的固化物具有以下特点:

①较高的压缩与拉伸强度;

②长期暴置在高温条件下仍能保持良好的力学性能;

③耐电弧性、耐紫外光老化性能及耐气候性较好。

characteristics of cycloaliphatic epoxy resin curing material:

①higher compression and tensile strength.

②maintain good mechanical performance when exposed at high temperature for a long time.

③strong arc resistance, good uv-aging properties and excellent weatherability.环氧树脂/酸酐体系由于粘度低,使用寿命长,固化放热量小,收缩率低,固化产物的耐热性高和力学性能优良而在国民经济的各个领域得到了极为广泛的应用。通常环氧树脂/酸酐体系在低温下固化速率非常缓慢,只能在高温时才能固化,当封装电子元器件时,过高的温度会损坏元器件,因此,有时需要用催化剂降低固化温度,同时加快固化速率。

cycloaliphatic epoxy resin/anhydride system has been widely used in various fields of the national economy due to its low viscosity, long service life, low curing heat, low shrinkage rate, strong heat resistance and excellent mechanical properties of curing products. the epoxy resin/anhydride system usually cures very slowly at low temperature and it can only be cured at high temperature. when electronic components are encapsulated, excessive temperatures may damage components, so catalysts are sometimes needed to reduce the curing temperature while speeding up the curing rate.

酸酐固化环氧树脂体系具有优异的机械物理性能和高温稳定性能。

anhydride-cured epoxy resin system possesses outstanding mechanical/physical properties and high-temperature stability.

酸酐的热固化反应分为无促进剂和有促进剂存在两种情况。

the thermal curing reaction by anhydrides is divided into two types: with promoter and without promoter.

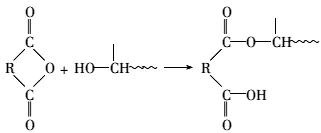

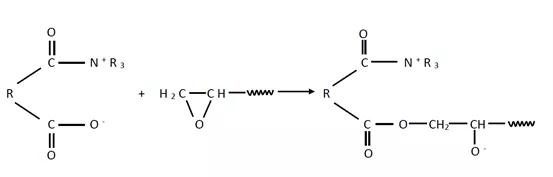

当无促进剂存在时,首先是环氧树脂中的羟基使酸酐开环,生成单酯和羧酸:

when in the absence of promoter, the hydroxyl group of the epoxy resin makes anhydride open ring to produce monoester and carboxylic acid.

羧酸对环氧基加成,生成二酯和羟基:

the carboxylic acid is added to the epoxy group to produce diester and hydroxyl group.

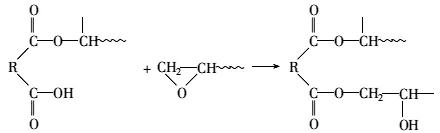

酯化生成的羟基与环氧基发生醚化反应:

the hydroxyl group obtained from esterification will react with epoxy group by etherification.

如此开环-酯化-醚化反应不断进行下去,直至环氧胶黏剂交联热固化。

as such, the ring opening-esterification-etherification reaction continues until the epoxy glue is cross-linked and thermally cured.

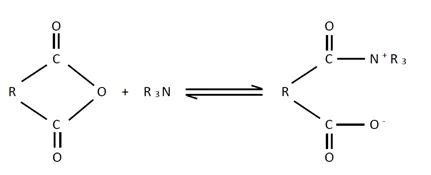

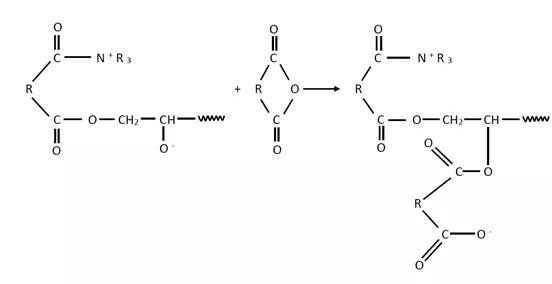

当有路易斯碱 (如叔胺)促进剂存在时,叔胺进攻酸酐,生成羧酸盐阴离子;此羧酸盐阴离子与环氧基反应生成烷氧阴离子;烷氧阴离子与别的酸酐反应,再生成羧酸盐阴离子。反应依次进行下去,逐步进行加成聚合,而使环氧树脂固化。有促进剂存在时,酸酐热固化反应生成的全是酯键,未发现有醚键生成。酸酐在促进剂存在时的热固化反应按如下历程进行。

when in the presence of louis alkali (e.g., tertiary amine) promoter, tertiary amine will attack anhydride to produce carboxylate anion. the carboxylate anion reacts with epoxy group to produce alkoxide anion. then the alkoxide anion reacts with another anhydride to produce another carboxylate anion. addition polymerization is gradually done for curing of epoxy resins. when the promoter exists, anhydride is thermally cured and reacted to produce ester bond rather than ether bond. please find the thermal curing mechanism of anhydride in the presence of the promoter as follows,

叔胺进攻酸酐生成羧酸盐阴离子:

the tertiary amine attacks anhydride to produce carboxylate anion.

羧酸盐阴离子与环氧基反应生成烷氧阴离子:

the carboxylate anion reacts with epoxy group to produce alkoxide anion.

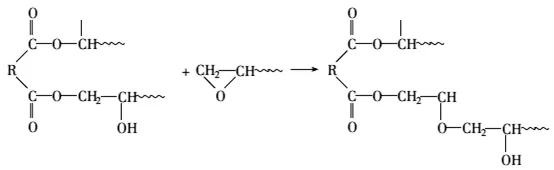

烷氧阴离子与另一个酸酐反应生成羧酸盐阴离子:

the alkoxide anion reacts with another anhydride to produce another carboxylate anion.

在促进剂存在时,环氧树脂的热固化速度也受体系内羟基浓度的支配。因此,添加促进剂对液态环氧树脂非常有效,120~150℃即能完成热固化反应。

when the promoter exists, the thermal curing speed of epoxy resin depends on the concentration of hydroxyl group in system. hence, it is extremely effective for liquid epoxy resins to add with the promoter. the thermal curing reaction can be done at a temperature range from 120℃ to 150℃.

脂环族环氧树脂 (环氧化脂环烯烃化合物) 是含有两个脂环环氧基的低分子化合物。本身不是聚合物,但是与固化剂作用后能生成性能优异的三维体型结构的聚合物。

cycloaliphatic epoxy resin (also called oxirane) is a low-molecular compound with two oxirane functional groups. it is not a polymer in itself, but it can react with the curing agent to create a high-performance, three-dimensional structured polymer.

脂环族环氧化合物的耐热性、力学性能及耐候性好,尤其是粘度小,适用期长,特別适用于湿法层压成型和缠绕成型制造高强度耐热复合材料。

cycloaliphatic epoxy compounds have many advantages, including low viscosity, long service life, good weatherability, strong heat resistance and excellent mechanical properties. they are especially suitable for use in manufacturing of high-strength and heat-resistant composites by wet type laminating and winding technique.

脂环族环氧化合物还可作塑料模具中的树脂组分,所得的固化物耐热性好,有较好的机械强度,体积收缩率小,精确度较高,适合做精密铸模和模具。比起金属模具,它具有易于加工、价格低、重量轻、利于模塑操作等优点。

the cycloaliphatic epoxy compound can also be used in the resin part of the plastic mold. it shows strong thermal resistance after curing. due to good mechanical strength, low volume shrinkage ratio and high precision, it is suitable for use in precision molds and dies. when compared with metal molds, it shows advantages of easy processing, low price, light weight, convenient molding operation, etc.

上一条: cycloaliphatic epoxy resin from synasia 下一条: three minutes to take you to study multifunctional epoxy resin