home > news > company news

application of cycloaliphatic epoxy resin in uv cationic light curing (2)

|

update: 2021-4-19 |

回顾上期内容,我们主要介绍了脂环族环氧树脂在uv光固化油墨和uv光固化涂料中的应用。在本期内容中,我们将重点介绍脂环族环氧树脂在sla型3d打印和uv光固化胶黏剂中的应用。南通新纳希新材料有限公司拥有十几年的脂环族环氧树脂生产经验,能为广大海内外客户提供优质产品和服务,致力于成为世界一流的化工新材料生产商和服务商。

in the previous article, we mainly introduced the application of cycloaliphatic epoxy resins in uv curing inks and uv curing coatings. in this article, we will focus on the application of cycloaliphatic epoxy resins in sla 3d printing and uv curable adhesives. nantong synasia new material co., ltd. has more than ten years of experience in the production of cycloaliphatic epoxy resins. we can provide customers at home and abroad with high-quality products and services. we are committed to becoming a world-class manufacturer and service provider of advanced chemical materials.

脂环族环氧树脂是含有两个脂环环氧基的低分子化合物。其本身不是聚合物,但是与固化剂作用后能生成性能优异的三维体型结构的聚合物。具有低粘度、热稳定性好、低卤素含量和优良电气性能、耐紫外线耐黄变优异、uv固化无氧阻聚、低迁移性等优势。

the cycloaliphatic epoxy resin is a low molecular compound containing two cycloaliphatic epoxy groups. it is not a polymer itself, but when reacting with the curing agent it can generate a polymer with excellent-performance three-dimensional structure. advantages include low viscosity, good thermal stability, low halogen content, great electrical performance, excellent uv-resistant and non-yellowing performance, low migration and no oxygen inhibition after uv curing, etc.

l sla型3d打印 / sla type 3d printing

l uv光固化胶黏剂 / uv curable adhesives

2.3 3d打印篇 / 3d printing

● 依照设备工艺不同,市场较成熟的uv光固化3d打印分为sla和dlp两种。

● according to different equipment processes, mature uv curing 3d printing in the market is divided into sla type and dlp type.

● dlp-3d打印通常使用光固化常用的自由基丙烯酸酯作为主要原料,以实现快速光固化成型。而相比dlp-3d,sla-3d通常打印工件体积更大,打印时间更长,需克服纯自由基光固化固有的氧阻聚和高收缩率等缺点。

● dlp-3d printing usually uses free radical acrylates as the main raw material to achieve rapid uv curing. compared with dlp-3d, sla-3d usually prints larger workpieces and spends longer printing time. it needs to overcome the inherent disadvantages of pure free radical uv curing such as oxygen inhibition and high shrinkage.

● sla-3d打印所采用的脂环族环氧树脂是由聚合物单体与预聚体组成,加有光引发剂 (光敏剂),一般为液态。脂环族环氧树脂经过一定波长的uv光照射后,引起聚合反应最终固化。

● the cycloaliphatic epoxy resin used in sla-3d printing is generally liquid, which is composed of polymer monomer and prepolymer, as well as photoinitiator (photosensitizer). after the cycloaliphatic epoxy resin is irradiated with a certain wavelength of uv light, it causes the polymerization reaction to finally cure.

● sla 3d打印用途 / sla-3d printing applications

l 航天航空领域 / aerospace

sla 模型可直接用于风洞试验,进行可制造性、可装配性检验

the sla model can be directly used in wind tunnel tests for manufacturability and assemblability inspection.

l 模具铸造领域 / mold casting

sla技术、fdm技术等快速成型技术的出现,为铸模生产提供了速度更快、精度更高、结构更复杂的保障

the emergence of rapid prototyping technologies such as sla technology and fdm technology provides the guarantee of faster speed, higher precision and more complex structure for the production of casting molds.

l 文化艺术领域 / culture and art

3d打印技术多用于艺术创作、文物复制、数字雕塑等,制作创意各种艺术工艺品,动漫小人,以及创意文化产品的模型制作

3d printing technology is mostly used for artistic creation, cultural relic reproduction, digital sculpture, etc., to produce various creative arts and crafts, cartoon villains, and model making of creative cultural products.

l 汽车领域 / automotive

利用光固化成型技术制作形状,结构十分复杂的零件原型,以验证设计人员的设计思想,并利用零件原型做功能性和装配性检验,还可在发动机的试验研究中用于流动分析

uv curable molding technology is used to make prototypes of very complex shapes and structures to verify the designer’s design ideas, and use the prototypes for functional and assembly inspections. it can also be used for flow analysis in engine test research.

l 生物医学领域 / biomedical field

sla技术可以制作具有生物活性的人工骨支支架,3d打印肝脏模型,3d打印头盖骨,3d打印耳蜗

sla technology can produce biologically active artificial bone scaffolds, 3d printed liver models, 3d printed skulls, and 3d printed cochlea.

l 设计领域 / design field

sla光固化技术将设计师大脑中的一切创意设计,立刻展现出现实

sla uv-curing technology brings all the creative designs in the designer's brain to show reality immediately.

由于脂环族环氧树脂具有低粘度、低溶胀、固化快、低收缩率、高光敏度的特点,在光固化领域有着极为广阔的应用前景,尤其在新兴市场——3d打印领域。

as cycloaliphatic epoxy resin has the characteristics of low viscosity, low swelling, fast curing, low shrinkage and high photosensitivity, it has extremely broad application prospects in the field of uv curing, especially in the emerging market like 3d printing.

基于脂环族环氧的阳离子固化体系,有收缩率低,机械强度高,不存在氧阻聚等优势,故广泛应用于 sla-3d打印配方。同时,脂环族环氧基团的引入,对提高机械性能和固化速度均有不同程度的帮助。

cycloaliphatic epoxy based cationic curing system has the advantages of low shrinkage, high mechanical strength and no oxygen inhibition, so it is widely used in sla-3d printing formulations. at the same time, the introduction of cycloaliphatic epoxy groups helps to improve mechanical properties and curing speed to varying degrees.

3d打印技术 / 3d printing technology

将机械、材料、计算机、通信、控制技术和生物医学等技术融合贯通,可以缩短产品开发周期,降低研发成本,形成一体制造复杂形状工件,改变制造生产模式,影响人类生活方式。

the integration of machinery, materials, computers, communications, control technology and biomedical technologies can shorten product development cycles, reduce r&d costs, form an integrated manufacturing of complex-shaped workpieces, change manufacturing and production modes, and affect human life style.

2.4 uv光固化胶黏剂 / uv curable adhesives

● 主要组分:预聚物、光引发剂、活性单体等组成,根据不同的需要还可加入增感剂、增塑剂、稳定剂、增粘剂、抗氧剂等各种助剂

● composition: prepolymer, photoinitiator, reactive monomer and various additives such as sensitizer, plasticizer, stabilizer, tackifier, antioxidant according to different needs

● 优点:固化速度快,生产线简化,生产过程环保,低voc,固化膜综合性能好

● advantages: fast curing, simplified production line, environmentally friendly production process, low voc, good overall performance of cured film

● uv光固化胶分类 / uv curable adhesive varieties:

l uv压敏胶(psa) / uv pressure sensitive adhesive

装饰膜、各种保护膜到工程结构胶带,广告板、电子产品、高端包装盒

decorative film, various protective films to structural tape, advertising boards, electronic products, high-end packaging boxes

l uv复合胶 / uv composite adhesive

食品、医药等包装材料的复合膜用胶

adhesives for composite film of packaging materials such as food and medicine

l uv建筑胶 / uv construction adhesive

商店橱窗和装修、彩色玻璃

shop windows and decoration, stained glass

l uv电子胶 / uv electronic adhesive

uv固化粘接是电子产品制造中必用的技术手段。随着电子产品的薄层化以及有机光电子器件、柔性可弯曲显示器件的出现,适应卷对卷工艺的uv粘合剂有巨大的需求

uv curable bonding is a necessary technical means in the manufacture of electronic products. with the thinning of electronic products and the emergence of organic optoelectronic devices and flexible bendable display devices, there is a huge demand for uv adhesives that adapt to the roll-to-roll process.

l uv光学胶 / uv optical adhesive

触摸屏目前是uv光学胶的最大单一应用。触摸屏中的uv光学胶有3个功能:粘接、增加透光性和提高抗冲能力。

touch screens are currently the largest application of uv optical adhesives. the uv optical adhesive in the touch screen has 3 functions: bonding, increasing light transmission and improving impact resistance.

l uv医用胶 / uv medical adhesive

医用压敏胶或胶带改为uv固化制备,可以形成系列产品。

medical pressure-sensitive adhesive or tape is changed to uv curing preparation, which can form a series of products.

光固化胶黏剂初始配方

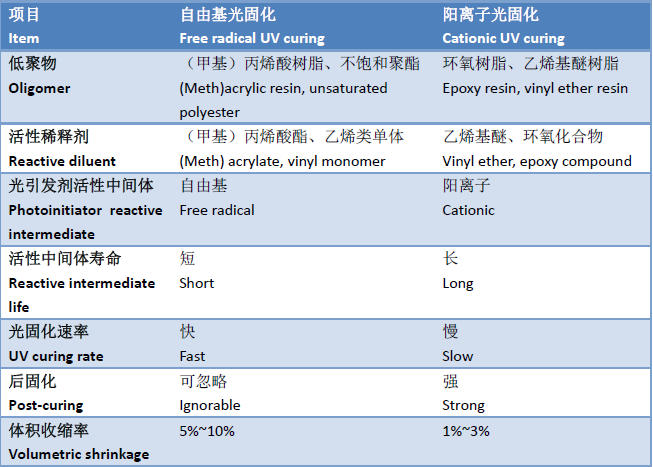

● 自由基光固化优势 / free-radical uv curing advantages

l 固化速度快 fast curing

l 性能易于调节 east-to-adjust performance

● 阳离子光固化优势 / cationic uv curing advantages

l 硬度高 high hardness

l 收缩体积小 small volumetric shrinkage

l 粘结强度高 high bond strength

l 耐磨 abrasion resistant

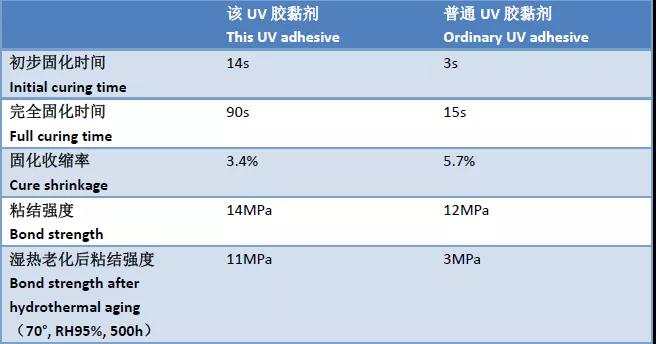

阳离子固化体系固化速度慢、齐聚物和活性稀释剂种类少、光引发剂价格高、固化产物性能不易调节等缺点。如果自由基、阳离子混杂光固化体系适当配合,则有望取长补短,得到固化速度快、体积收缩小、胶层内应力小、粘接强度高的光固化胶粘剂。

cationic curing system has the disadvantages of slow curing speed, few types of oligomers and reactive diluents, high price of photoinitiators, and difficult adjustment of cured product performance. if the free radical and cationic hybrid uv curing system are properly combined, it is expected to learn from each other's strengths, and obtain a uv-curable adhesive with fast curing speed, small volume shrinkage, low internal stress of the adhesive layer and high bonding strength.

双重固化技术是将uv固化与其他固化方式结合起来的固化技术。由于uv光固化存在着自身的缺点: 只有uv光能照射到的地方才能固化,uv光照不到的地方很难固化完全。而双重固化方式结合了各种聚合反应的优点,表现出很好的协同效应。将双重固化技术应用于胶粘剂的研制,必将赋予uv固化胶粘剂更强大的竞争力。双重固化胶粘剂由于有暗反应的帮助,可以克服光固化胶粘剂的很多限制,可以扩展uv固化体系在不透明的材质之间、形状复杂的基材上、超厚涂层及有色涂层等中的应用。

dual curing technology combines uv curing with other curing methods. uv curing has its own shortcomings: it can be cured only where uv light can be irradiated, and it is difficult to cure completely where uv light is not irradiated. the dual curing method combines the advantages of various polymerization reactions and shows a good synergistic effect. the application of dual curing technology to the development of adhesives will definitely give uv curing adhesives more powerful competitiveness. with the help of dark reaction, dual-curing adhesives can overcome many limitations of uv-curing adhesives. they make the uv curing system applicable to opaque materials and complex-shaped substrates, as well as ultra-thick coatings and colored coatings.

总结 summary

当前,世界经济整体加速向低碳化深入发展,节能减排、绿色能源、可持续发展等逐渐成为世界各国关注的焦点。光固化材料在固化时非常快速且无溶剂挥发,大大降低了对环境的污染,近年来作为一种环境友好的绿色材料得到了蓬勃的发展,应用的范围越来越广。随着高性能树脂和光引发剂品种的增多,固化技术的不断创新,光固化应用领域越来越多,为人们带来了越来越多的优质的产品。

at present, global economy is accelerating towards low-carbon development. energy conservation, emission reduction, green energy and sustainable development have gradually become the focus of every country around the world. uv-curing materials can provide very fast, solvent-free curing speed, which greatly reduces environmental pollution. in recent years, as an environmentally friendly green material, it has developed vigorously and has a wider range of applications. with the increase in the varieties of high-performance resins and photoinitiators, as well as the continuous innovation of curing technology, more and more uv curing applications have brought more and more high-quality products to people.

上一条: application of cycloaliphatic epoxy resin in uv cationic light curing (1) 下一条: take you to understand uv curing coatings in one minute