home > news > company news

how to choose the photoinitiators?

|

update: 2021-9-28 |

uv固化技术具有环境污染小、固化速度快、能耗低等特点。它是油墨、涂料、印刷和包装领域增长最快的细分市场。uv固化树脂体系主要由光引发剂、活性低聚物、活性稀释剂等助剂组成。

uv-curing technology is characterized by less environmental pollution, fast curing speed, low energy consumption. it is the fastest growing market segment in the ink, coating, printing and packaging fields. uv-curing resin system is mainly composed of photoinitiator, reactive oligomer, active diluent and other additives.

光引发剂是紫外光固化树脂体系的关键成分,对固化速度起着决定性作用。根据反应机理不同,光引发剂可分为自由基型和阳离子型。本文中我们将介绍不同自由基光引发剂的应用。

photoinitiator is the key component of uv-curing resin system, which plays a decisive role in curing rate. according to different reaction mechanism, photoinitiators can be divided into free radical type and cationic type. in this post, we will introduce you the application of different free radical photoinitiators.

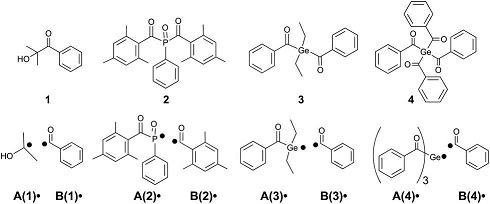

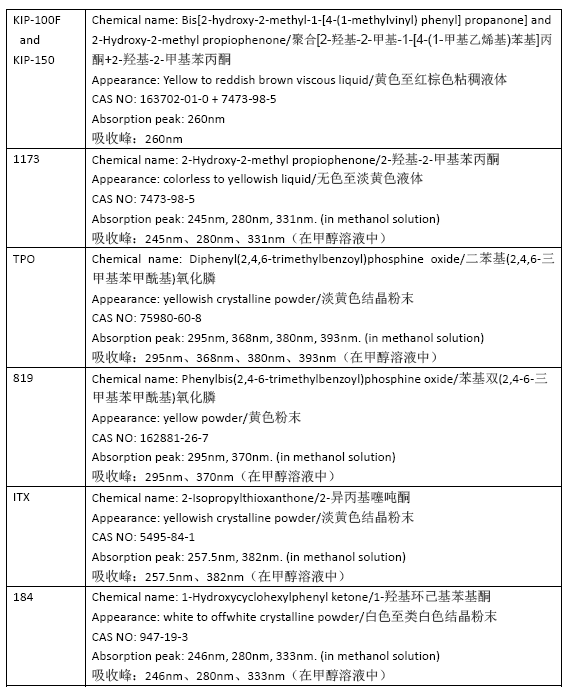

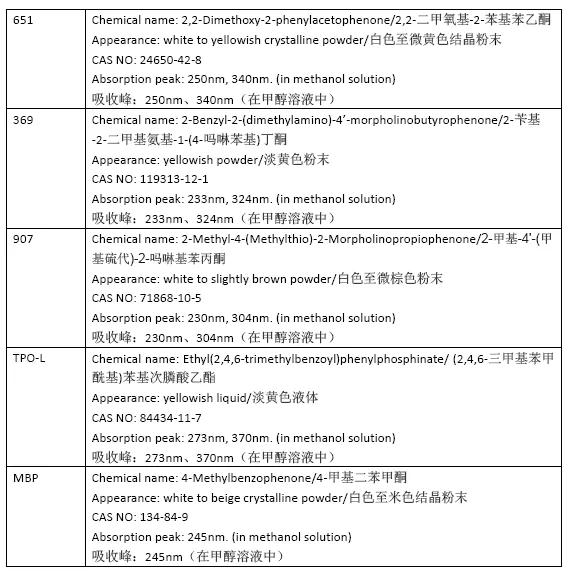

常用自由基光引发剂common free-radical photoinitiators

主要自由基光引发剂介绍main free-radical photoinitiator introduction

kip-100f和kip-150光引发剂

kip-100f and kip-150 photoinitiator

kip-100f和kip-150特别适用于需要极低固化气味和颜色稳定性的uv固化体系的光聚合。当在与水相容的溶剂中预稀释时,它适用于水基 uv 固化体系。主要应用包括粘合剂、印刷油墨、地板涂料、木材、塑料、纸张、金属和光纤的清漆。最佳浓度为0.5%至5%(重量),具体取决于系统组成、厚度和所需的固化速度。

kip-100f is particularly indicated for the photopolymerisation of uv curable systems when very low curing odor and colorstability are required. it is suitable for water based uv curable systems when prediluted in a water compatible solvent. main applications include adhesives, printing inks, coatings for flooring,clear lacquers for wood, plastic, paper, metal and optical fibers. optimum concentration is between 0.5 and 5% by weight and depending on system composition, thickness, and desired cure speed.

kip-150是一种高分子型光引发剂,与树脂体系的混溶性较好,低挥发、低迁移,还可制成水乳液,成为水性光固化引发剂。kip-150分子链上含有多个引发剂单元,光辐照时可在一个大分子上同时形成多个自由基,局部自由基浓度可以很高。局部高浓度效应可以有效对付氧阻聚,有利于加速光聚合,但大分子内活性自由基相互互偶合终止的几率也会增加,通过设计分子结构,可以降低分子内自由基偶合。

kip-150 is a polymeric photoinitiator with good miscibility with resin systems, which provides low volatility and low migration. it can also be made into water emulsion and used as water-based photocuring initiator. the molecular chain of kip-150 contains multiple initiator units, which can simultaneously form multiple free radicals on one macromolecule when irradiated by light, and the local free radical concentration can be very high. the local high concentration effect can effectively deal with oxygen inhibition and accelerate photopolymerization, but the probability of mutual coupling termination of active free radicals in macromolecules will also increase. by designing molecular structure, intramolecular free radical coupling can be reduced.

新纳希生产的光引发剂kip-100f由1173和kip-150组成。基于高反应性、低气味和颜色稳定性佳的特点,kip-100f通常应用于各类涂料和胶粘剂等,涉及行业包括塑料、木器、金属等。

the photoinitiator kip-100f produced by synasia is composed of 1173 and kip-150. due to the characteristics of high reactivity, low odor and good color stability, kip-100f is generally used in various coatings and adhesives, etc. it involves in industries like plastics, wood, metal, etc.

1173光引发剂

1173 photoinitiator

1173是一种高效、不黄变的紫外光引发剂。该不饱和聚酯光固化体系具有低气味、不黄变、颜色稳定性好等特点。

1173 is a high-efficiency, non-yellowing uv photoinitiator. the uv curing system of unsaturated polyester system has the characteristics of low odor, non-yellowing and good color stability.

1173是一种多功能液体光引发剂,可用于纸张、金属和塑料表面的丙烯酸系列uv固化清漆。特别推荐用于即使长时间暴露在阳光下也只需要轻微泛黄的uv涂料。1173具有良好的相容性,可以很容易地与其他光引发剂和预聚物混合。

1173 is a multifunctional liquid photoinitiator, which can be used for the acrylicseries of uv-curable varnishes on paper, metal and plastic surfaces. it is especially recommended for uv coatings that require only slight yellowing even when exposed to sunlight for a long time. 1173 has good compatibility and can be easily mixed with other photoinitiators and prepolymers.

tpo光引发剂

tpo photoinitiator

tpo性能优良,通常与仲胺、叔胺配合使用,已广泛应用于涂料、油墨、粘合剂、缓蚀剂、焊料等行业。21世纪以来,tpo引发剂在uv固化领域得到了广泛推广和应用。

tpo has excellent performance and is often used in combination with secondary amine and tertiary amine. it has been widely used in coatings, inks, adhesives, corrosion inhibitors, solders and other industries. since 21st century, tpo initiator has been widely promoted and applied in the field of uv curing.

tpo的长紫外波长吸收范围较宽。其有效吸收峰为350nm~400nm,一直吸收到420nm波长。其吸收峰比常规引发剂长。正因如此,tpo光引发剂被广泛应用于光固化涂料、印刷油墨、光固化胶粘剂、光纤涂料等领域。并且由于其光漂白作用,光引发剂tpo专门用于厚膜和白色系统。它可以在白色或高钛白粉的着色表面上完全固化。tpo引发剂还可用于透明涂料,特别是对气味要求低的产品。

tpo has a wide range of long uv wavelength absorption. its effective absorption peak is 350nm ~ 400 nm, and absorbs all the way to 420 nm wavelength. its absorption peak is longer than that of conventional initiator. because of this, tpo photoinitiator is widely used in many applications, such as ultraviolet curing coatings, printing inks, ultraviolet curing adhesives, optical fiber coatings, etc. and because of its function of photobleaching, tpo is specially used in thick film and white systems. it can be completely cured on the pigmented surface of white or high titanium dioxide. tpo initiator can also be used for transparent coatings, especially for products with low odor requirements.

819光引发剂

819 photoinitiator

819是bapo型光引发剂之一,可吸收430nm以上的近可见光区中较长波长的紫外光。该波长的光更深地穿透涂层的较厚层,从而实现完全固化效果。较短波长的光(大约230nm)具有更高的光子能量,但与较长波长的光相比穿透性较差。这种较短波长的光对于表面固化特别有用。

819 is one of bapo type photoinitiators, which absorbs longer wavelength uv light in the near visible region above 430nm. light of this wavelength penetrates deeper into the thicker layers of the coating, thus enabling the through curing effect. shorter wavelength light, around 230nm, is of higher photon energy but is less penetrating than that of longer wavelengths. light of this shorter wavelength is particularly useful for surface curing.

酰基氧化膦光引发剂819作为一种新型光引发剂,以其优异的性能被广泛应用于涂料、油墨、粘合剂等行业。它们在紫外线和可见光区域具有更大的吸收,并且可以比其他光引发剂更有效地引发固化,用于含颜料的涂料。酰基氧化膦光引发剂固化和长期光照后不易变黄,可用于对变黄要求较严格的场合,如白色、浅色油墨、油漆等。此外,酰基氧化膦对光有漂白作用,可以穿透涂层,帮助厚膜彻底固化。

as a new type of photoinitiator, acylphosphine oxides, such as photoinitiator 819, have been widely used in coatings, inks, adhesives and other industries for their excellent properties. they have greater absorption in the ultraviolet andvisible regions, and can initiate curing more effectively than other photoinitiators for coatings containing pigments. acyl phosphine oxide photoinitiators hardly yellows after curing and long-term light radiation, sothey can be used in occasions where yellowing requirements are stricter, suchas white, light ink and paint. in addition, acylphosphine oxides have bleaching effect on light, which can penetrate the coating and help the thick film to be cured thoroughly.

此外,光引发剂819还可用于有色紫外线固化塑料涂料。uv涂料因其优异的性能和高效的生产效率,已广泛应用于各种电子、家电产品的塑料外壳。但是,uv涂料加色后深度固化不好,导致涂膜附着力差,uv树脂对颜料的分散和排列差,严重影响涂膜外观,所以传统的施工工艺是先涂以溶剂型有色底漆进行着色,烘烤后再涂上uv清漆,以提高漆膜表面的物理性能。

in addition, photoinitiator 819 can also be used in colored uv curable plastic coatings. because of its excellent performance and efficient production, uv coatings have been widely used in plastic shells of various electronic and household appliances products. however, the deep curing of uv coatings after color addition is not good, resulting in poor film adhesion, and the dispersion and arrangement of uv resins to pigments is poor, seriously affecting the appearance of the film, so the traditional construction process is to first coat solvent-based colored primer for coloring, after baking and then coated with uv varnish to improve the physical properties of the film surface.

itx光引发剂

itx photoinitiator

itx是一种高效的自由基ii型光引发剂,用于对应树脂和叔胺的uv固化。

itx is a highly effective free radical type ii photoinitiator, which uses for uv curing of corresponding resin and tertiary amine.

itx用于丝网印刷油墨、清漆、平版油墨、柔版油墨、电子产品和木器涂料。也可用作光敏剂,增强uv 907的固化性能。吸收峰为258-382 nm。推荐用量为 0.2-2%。

itx is used in screen printing inks, varnishes, lithographic inks, flexo inks, electronic products, and wood coatings. it can also be used as a photosensitizer to enhance the curing properties of uv 907. the absorption peak is 258-382 nm. recommended amount is 0.2-2%.

184光引发剂

184 photoinitiator

1-羟基环己基苯基酮较通俗的名称是光引发剂184。作为最常用的光引发剂之一,1-羟基环己基苯基酮具有良好的抗黄变能力和低异味。其在甲醇溶液中的吸收峰为246nm、280nm、333nm,故主要吸收短波长紫外光。1-羟基环己基苯基酮用于引发化学不饱和预聚物的光聚合,例如丙烯酸酯与单官能或多官能乙烯基单体结合使用。

the more popular name of 1-hydroxycyclohexyl phenyl ketone is photoinitiator 184. as one of the most commonly used photoinitiators, 1-hydroxycyclohexyl phenyl ketone has good yellowing resistant ability and low oddor. its absorption peak in methanol solution is 246nm, 280nm, 333nm, so it mainly absorbs short wavelength uv light. 1-hydroxycyclohexyl phenyl ketone is used to initiate the photopolymerisation of chemically unsaturated prepolymers – e.g. acrylates – in combination with mono- or multifunctional vinyl monomers.

实验表明:紫外线的波长越长,穿透性越强,越容易到达薄膜的深层,而波长越短,越难到达薄膜的深层。所以1-羟基环己基苯基酮有利于表面固化。如果用于较厚的薄膜配方,它通常与光引发剂819共同引发,以达到表面和基底的平衡效果。

experimentshows that: the longer the wavelength of the uv light is, the stronger the penetrability is, the easier it is to reach the deep layer of the film, while the shorter the wavelength is, the harder it is to reach the deep layer of the film. so 1-hydroxycyclohexyl phenyl ketone is good for surface curing. if for thicker film formulation, it often co-initiates with photoinitiator 819 to achieve the balance effect both on surface and base.

南通新纳希新材料有限公司以具有竞争力的价格生产高质量的脂环族环氧树脂和各类紫外光引发剂,如kip,1173等。请与我们联系以获取更多信息。

nantong synasia new material co., ltd. produces cycloaliphatic epoxy resins and various uv photoinitiators such as kip, 1173, etc. in high quality with competitive price. please contact us for more information.

上一条: transition from traditional manufacturing to 3d printing 下一条: application of epoxy resins for insulation in high-voltage electrical applicances