利来国际w66首页 > 新闻中心 > 公司新闻

脂环族环氧树脂在uv阳离子光固化中的应用

|

更新日期: 2021-3-29 |

uv光固化技术是一种高效、环保、节能、优质的面向21世纪的新技术,广泛应用于涂料、胶黏剂、油墨、光电子等领域。

uv curing technology is a high-efficiency, environmentally friendly, energy-saving, advanced technology in the 21st century, which is widely used in coatings, adhesives, inks, optoelectronics and other fields.

自1946年美国inmont公司取得第一个uv光固化油墨专利、1968年德国bayer公司开发了第一代uv光固化木器涂料以来,光固化涂料在全球获得迅速发展。近几十年来,一大批新型、高效的光引发剂、树脂、单体和先进的uv光源被应用于uv光固化行业,促进了行业的发展。

since the american inmont company obtained the first uv curable ink patent in 1946, and the german bayer company developed the first generation of uv curable wood coatings in 1968, uv curable coatings have developed rapidly all over the world. in recent decades, a large number of new and efficient photoinitiators, resins, monomers and advanced uv light sources have been applied to the uv curing industry, which has promoted industry development.

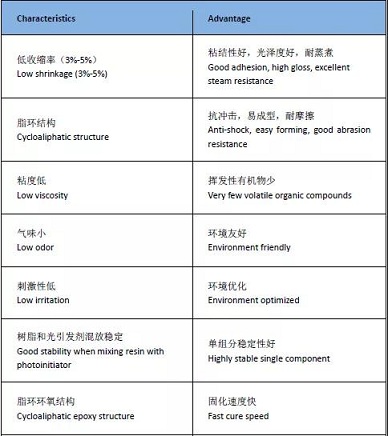

脂环族环氧树脂是含有两个脂环环氧基的低分子化合物。其本身不是聚合物,但是与固化剂作用后能生成性能优异的三维体型结构的聚合物。具有低粘度、热稳定性好、低卤素含量和优良电气性能、耐紫外线耐黄变优异、uv固化无氧阻聚、低迁移性等优势。

the cycloaliphatic epoxy resin is a low molecular compound containing two cycloaliphatic epoxy groups. it is not a polymer itself, but when reacting with the curing agent it can generate a polymer with excellent-performance three-dimensional structure. advantages include low viscosity, good thermal stability, low halogen content, great electrical performance, excellent uv-resistant and non-yellowing performance, low migration and no oxygen inhibition after uv curing, etc.

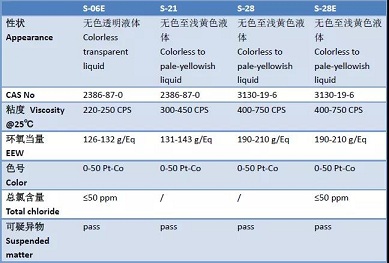

主要的脂环族环氧树脂

uv光固化油墨 / uv curable inks

uv光固化涂料 / uv curable coatings

2.1 uv光固化油墨篇 / uv curable inks

● 组成:uv树脂,单聚物(通常在普通油墨作为溶剂,降粘,参与化学反应),添加剂,光引发剂

● composition: uv resin, monomer (used as solvent in ordinary ink for reduced viscosity), additive, photoinitiator

● 优势:低voc, 无溶剂,干燥速度快,光泽度好,色彩鲜艳,耐水耐溶剂,耐磨

● advantages: low voc, solvent free, fast drying speed, high gloss, brilliant color, strong resistance to moisture / solvent / abrasion.

● 应用领域 / applications

uv油墨品种:uv研磨,uv冰冻,uv发泡,uv起皱,uv凸字,uv折光,uv点缀, uv上光油的特殊包装印刷油墨。

uv ink varieties: uv grinding, uv freezing, uv foaming, uv wrinkling, uv lettering, uv refracting, uv decorating, uv varnishing when used for printing inks in special packaging.

uv油墨印刷技术:uv胶印油墨、uv丝印油墨、uv移印油墨、uv水性喷墨油墨。

uv ink printing technology: uv offset printing ink, uv screen printing ink, uv pad printing ink, uv water-based inkjet ink

uv油墨应用领域:uv印铁油墨、uv金属油墨、uv玻璃油墨、uv塑料油墨、uv电路版油墨、uv感光油墨。

uv ink application: uv tin printing ink, uv metallic ink, uv glass ink, uv plastic ink, uv circuit board ink, uv photosensitive ink

发展前景 / prospects

uv光固化油墨适用于各种基材,可替代溶剂型油墨或水性油墨。

uv curable inks are suitable for various substrates. they can replace solvent-based inks or water-based inks.

全球uv光固化油墨市场将于2020年达到35亿美元,2015-2020年间的复合年均增长率超过15.7%。由于包装食品及饮料行业的增长带动了标签印刷需求的上升,成为uv油墨的主要增长领域。

the global uv curable ink market will reach 3.5 billion u.s. dollars in 2020, with a compound annual growth rate of more than 15.7% between 2015 and 2020. as the growth of the packaged food and beverage industry has driven the increase in demand for label printing, it has become a major growth area for uv inks.

2.2 uv光固化涂料 / uv curable coatings

● 组成:颜料/添料/助剂,光引发剂,活性稀释剂,低聚物

● composition: pigment/additive/auxiliary, photoinitiator, reactive diluent, oligomer

● 优势:固化快,低voc,成本低,浪费少,节约能源,性能好(硬度高,耐磨好,透明度高,质量好)

● advantages: fast curing, low voc, low cost, less waste, energy saving, outstanding performance (high hardness, good abrasion resistance, high transparency, good quality)

● 应用 / applications

木器涂料/wood coating:

家具、门窗、护墙板、地板、日常生活用品、木制乐器、体育用品、文具、儿童玩具

furniture, doors and windows, wall panels, flooring, daily necessities, wooden musical instruments, sporting goods, stationery, children's toys

印刷材料 / printing material

高档的香烟,化妆品,食品包装等印刷材料

high-end printing materials for cigarettes, cosmetics, food packaging, etc.

塑料涂料 / plastic coating

手机、电视机、电脑、汽车、摩托车配件等领域

mobile phones, tvs, computers, automobiles, motorcycle accessories and other fields

罩印清漆 / overprint varnish

涂于面漆之上形成保护装饰图层的清漆

apply on top coat to form a varnish that protects the decorative layer.

光纤涂覆材料 / optical fiber coating material

保护光导玻璃纤维免受外界环境影响、保持其足够的机械强度和光学性能的涂料

a coating that protects the optical glass fiber from the external environment and maintains its sufficient mechanical strength and optical performance

发展前景 / prospects

uv光固化涂料在光纤涂层、木材、饮料罐、食品包装、医疗器械和汽车行业中应用日趋成熟。

uv curable coatings are becoming more and more mature in different industries, such as optical fiber coatings, wood, beverage cans, food packaging, medical equipment and automotive industries.

预计全球uv固化涂料市场将从2020年的65亿美元增长到2025年的114亿美元,复合年增长率在预测期内为12.0%。预计政府将着重采用清洁燃料以及自然和燃料电池电动汽车数量的增长来推动市场发展。

the global uv curing coatings market is expected to grow from usd 6.5 billion in 2020 to usd 11.4 billion in 2025, with a compound annual growth rate of 12.0% during the forecast period. the government is expected to focus on the adoption of clean fuels and the growth in the number of natural and fuel cell electric vehicles to promote market development.

关于3d打印篇和uv光固化胶黏剂篇,我们将在下期内容中具体讲解不同行业中的应用、技术参考和发展前景,大家千万不要错过哦~

regarding 3d printing materials and uv curing adhesives, we will specifically explain their applications, technical references and development prospects in different industries in the next content. don't miss it~

总结 summary

当前,世界经济整体加速向低碳化深入发展,节能减排、绿色能源、可持续发展等逐渐成为世界各国关注的焦点。光固化材料在固化时非常快速且无溶剂挥发,大大降低了对环境的污染,近年来作为一种环境友好的绿色材料得到了蓬勃的发展,应用的范围越来越广。随着高性能树脂和光引发剂品种的增多,固化技术的不断创新,光固化应用领域越来越多,为人们带来了越来越多的优质的产品。

at present, global economy as a whole is accelerating towards low-carbon development. energy conservation, emission reduction, green energy and sustainable development have gradually become the focus of every country around the world. uv-curing materials can provide very fast, solvent-free curing speed, which greatly reduces environmental pollution. in recent years, as an environmentally friendly green material, it has developed vigorously and has a wider range of applications. with the increase in the varieties of high-performance resins and photoinitiators, as well as the continuous innovation of curing technology, more and more uv curing applications have brought more and more high-quality products to people.

上一条: 新纳希给您拜年啦! 下一条: 脂环族环氧树脂在uv阳离子光固化中的应用(二)