利来国际w66首页 > 新闻中心 > 公司新闻

浅谈由传统制造到3d打印的转变

|

更新日期: 2021-8-27 |

传统制造方法有三种:减材、增材和等材制造。

there are three traditional manufacturing methods, including subtractive, additive and equal material manufacturing.

减材制造/subtractive manufacturing

减材制造是传统的金属切削加工,是用刀具从工件上切除多余材料,从而获得形状、尺寸精度及表面质量等合乎要求的零件的加工过程。缺点是边角料太多,非常容易造成材料的浪费问题。

subtractive manufacturing is a traditional metal cutting method, which is used to remove excess materials from the workpiece, thereby satisfying the requirements for shape, dimensional accuracy and surface quality on parts. the disadvantage is that there are too many leftover materials, which is very easy to cause waste.

等材制造/equal material manufacturing

等材制造通俗来说就是将一块泥巴捏成各种各样的形状,材料不多不少,比如说古代的打铁技术以及现在往模具里面注入材料等等。优点是不浪费材料,缺点是铸造锻炼耗费时间长速度慢,模具注入的开模成本高。

equal material manufacturing, for example, is to pinch a piece of mud into a variety of shapes. other examples include ancient iron-hitting technology, mold injecting technology and so on. the advantage is no waste and the disadvantage is very slow casting process and high mold cost.

增材制造/additive manufacturing

增材制造是采用材料逐渐累加的方法制造实体零件的技术,相对于传统的材料去除、切削加工技术,是一种“自下而上”的制造方法,这种通过逐层累积堆叠的方式来构造物体的打印方式就是3d打印。通常有三个步骤:

1、数字建模,设计形态

2、软件切片,分明层次

3、机器打印,逐层堆积

additive manufacturing is the technology of manufacturing solid parts by the method of material accumulation. unlike traditional material removal and cutting technology, it is a "bottom-up" manufacturing method, which constructs the object layer by layer. that is called 3d printing. usually there are three steps:

1. digital modeling for shape design

2. slicer software for clear hierarchy

3. mechanical printing for lay-by-layer construction

增材制造就是3d打印

am is 3d printing

3d打印本质是增材制造(am)技术,依托计算机辅助设计(cad)、大数据、云计算、计算机辅助制造(cam)、物联网、虚拟现实(vr)等技术支撑,将数字化或电脑模型,通过逐层堆积的方式而直接形成3d物体的制造工艺。3d打印(增材制造)是制造业有代表性的颠覆性技术,集合了信息网络技术、先进材料技术与数字制造技术,是先进制造业的重要组成部分。

the essence of 3d printing is additive manufacturing (am) technology. relying on computer-aided design (cad), big data, cloud computing, computer-aided manufacturing (cam), internet of things, virtual reality (vr) and other technology support, it can directly construct 3d objects layer by layer with digital or computer models. 3d printing (additive manufacturing) is a representative and disruptive technology of manufacturing industry, which combines information and network technology, advanced material technology and digital manufacturing technology. it is an important part of advanced manufacturing industry.

与传统制造技术(减材制造、等材制造)相比,3d打印(增材制造)不需要事先制造模具,不必在制造过程中去除大量的材料,也不必通过复杂的锻造工艺就可以得到最终产品,具有“去模具、减废料、降库存”的特点。在生产上可以优化结构、节约材料和节省能源,极大地提升了制造效率,同时实现“设计引导制造”理念。

compared with traditional manufacturing technology (subtractive manufacturing and equal material manufacturing), 3d printing (additive manufacturing) does not require the prior manufacture of molds. more importantly, there is no need to remove a large number of materials in the manufacturing process or go through the complex forging process to obtain the final product. it possesses "de-molding, waste reduction, inventory reduction" characteristics. in production, we can optimize the structure, save materials and save energy, which has greatly improved manufacturing efficiency, while realizing the concept of "design-led manufacturing".

增材制造

additive manufacturing

国际标准化组织辖下增材制造技术委员会发布iso/astm 52900:2015标准将增材制造技术分为7大类,分别是:立体光固化(sla)、粘结剂喷射(3dp)、定向能量沉积(ded)、薄材叠层(lom)、材料挤出(fdm)、材料喷射(ployjet)、粉末床熔融(slm、sls、ebm)。

the iso/astm 52900:2015 standard issued by the additive manufacturing technical committee classifies additive manufacturing technology into seven categories: stereolithography (sla), binder jetting (3dp), directional energy deposition (ded), thin material lamination (lom), material extrusion (fdm), material injection (ployjet), powder bed melting (slm, sls, ebm).

从产业链整体来看,3d打印上游涵盖激光器、振镜、三维扫描设备、3d打印软件、粉末原材料等;中游以3d打印设备生产厂商为主,部分也同时提供打印服务及原材料供应,在整个产业链中占据主导地位;下游行业应用已覆盖航天航空、汽车工业、船舶制造、能源动力、轨道交通、电子工业、模具制造、医疗健康、文化创意、建筑等各领域。

let’s take a look at the whole industrial chain. 3d printing upstream covers lasers, vibration mirrors, 3d scanning equipment, 3d printing software, powder raw materials, etc. 3d printing midstream dominates the entire industrial chain. it includes 3d printing equipment manufacturers mainly, as well as some printing service providers and raw material suppliers. 3d printing downstream has been applied in all fields including aerospace, automotive industry, shipbuilding, energy power, rail transportation, electronics industry, mold manufacturing, medical and health care, cultural creativity, architecture, etc.

sla快速成型

sla fast forming

sla快速成型

sla是目前国内外最深入、应用最广泛的快速成形技术之一,其技术成熟度高,也经过了市场长时间的检验,具体优势如下: 无需切削工具与模具,加工速度快,产品生产周期短;可以加工结构外形复杂或使用传统手段难于成型的原型和模具;以三维数字模型为基础进行数字化3d打印,可降低设计错误造成的高额往复制作/修复的成本;相比fdm成型工艺,sla成型精度高,表面光滑平整、成型速度快。

sla is currently one of the most in-depth, widely used fast forming technology at home and abroad. its high technical maturity has undergone a trial of market for a long time. its specific advantages are as follows: no cutting tools or molds, fast processing speed and short production cycle. sla is able to process complex structures, as well as molds and prototypes which may not be formed by conventional methods. it has realized digital 3d printing based on 3d digital models, which can reduce the cost of replication/repair caused by design errors. compared to fdm molding process, sla offers high molding accuracy, smooth surface flatness and fast molding speed.

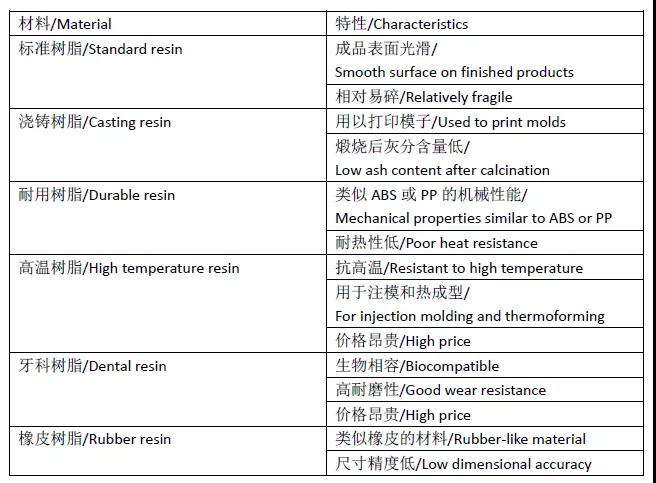

常用的sla材料/commonly used sla materials

sla材料为液体树脂,如浇注料或牙科树脂。下表总结了常用树脂的优缺点:

sla uses liquid resin as raw material, such as castable or dental resin. the following table summarizes the advantages and disadvantages of common resins:

后处理/post-processing

sla模型可以通过各种后处理方法,如砂光、抛光、喷涂涂层和使用矿物油等,获得非常高的品质。

sla models can achieve very high quality through a variety of post-processing methods, such as sanding, polishing, coating and the use of mineral oils, etc.

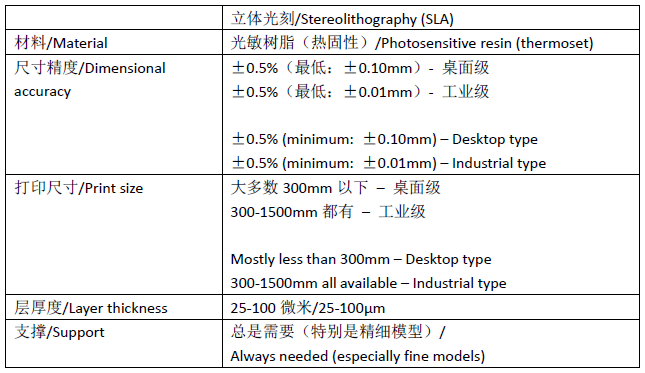

sla的主要特点总结如下表:

main features of the sla are summarized in the following table:

近年来,随着3d打印产业的不断发展,sla光固化3d打印机型及光敏树脂造价的逐渐走低,成为制作工业原型、展示模型、动漫手办等应用的最理想的选择之一。

with the continuous development of 3d printing industry in recent years, price of both sla 3d printer and photosensitive resin has become gradually lower. it has been one of the most idea choices for industrial prototypes, display models, animation and other applications.

未来趋势/future trend

在速度方面,立体光固化仍然存在速度方面的待加强。

in terms of speed, stereolithography still needs to be improved.

耗材方面,在这个呼吁节能环保的方向上,仍然是一个问题,开发新的成型材料,在强度,精度,性能及使用寿命加强,同时最好向环境友好型发展。

in terms of consumables, energy conservation and environmental protection is still an issue. develop new molding materials, enhance the strength, precision, performance and service life, while preferably leading to an environment-friendly development.

精度方面,如果向更高的生物医疗或电子行业,仍然需要一个大的改进。

in terms of accuracy, a big improvement is still needed for more advanced biomedical or electronics industries.

领域拓展,除了产品验证,快速模具上,去发展并渗透到其他的行业领域。

in terms of field expansion, develop and penetrate into other industries in addition to product validation and fast molding.

由于脂环族环氧树脂具有低粘度、低溶胀、固化快、低收缩率、高光敏度的特点,在光固化领域有着极为广阔的应用前景,尤其在新兴市场——3d打印领域,下游客户对高性能配方的追求以及政府对环保要求的提高,必定会推动脂环族环氧树脂需求的持续增长。

cycloaliphatic epoxy resin has an extremely board application prospect in uv curing field because of its low viscosity, low swelling ratio, low shrinkage rate, fast cure and high photosensitivity. especially in 3d printing emerging market, where customers seek for high-performance formulation and the government has raised demand for environmental protection, it will undoubtedly drive a continued increase in demand for cycloaliphatic epoxy resins.

南通新纳希新材料有限公司专业从事脂环族环氧树脂生产已十余年,欢迎海内外客户来电垂询,我们将竭诚为您服务!

nantong synasia new material co., ltd. has specialized in the production of cycloaliphatic epoxy resins for more than ten years. welcome customers at home and abroad to call us, and we will be happy to offer you premium service!

上一条: s-186树脂在碳纤维缠绕成型复材中应用 下一条: 哪种自由基型光引发剂适合你