home > news > company news

application of epoxy resins for insulation in high-voltage electrical applicances

|

update: 2021-10-22 |

绝缘材料的应用极为悠久,在二十世纪初期,欧洲国家就已经开始着手研究这一材料了,当时主要是通过采用高压定子线圈作为主要的原材料,随后美国等国家也开始着手研究,使得绝缘材料层出不穷。而我国直至二十世纪六七十年代才开始研究这一技术,利用酸性聚酯合成了绝缘材料,这些绝缘材料的应用可谓是打响了我国材料发展史上的第一枪。从此以后,我国还继续开发出了许多绝缘性技术。环氧树脂便是基于这一时代背景下产生的一种绝缘性技术,它的应用对于整个电力行业发展有着重要的意义。

the application of insulating material has a long-standing history. in the early 20th century, european countries began to study this material. at that time, high-voltage stator coil was mainly used as raw material. then the united states and other countries also began to study, which made insulating material emerge in endlessly. however, china did not begin to study this technology until the 1960s and 1970s, using acidic polyester to synthesize insulating material. the application of these insulating materials can be said to be the first shot in the history of material development in our country. since then, china has continued to develop many insulation technologies. epoxy resin is an insulating technology based on the background of this era. its application is of great significance to the development of the entire power industry.

随着社会经济的飞速发展和高压电器的日益增多,高压电器绝缘问题越来越受到人们的重视。环氧树脂在目前的高压电器绝缘系统中最为常见,它的应用对于整个电力系统安全有着重要意义。随着电压的不断增加,电气绝缘系统要求越来越严格,大容量发电技术的发展促使着电力电压的提升,也不断使得绝缘材料进步与优化。

with the rapid development of social economy and the increasing number of high-voltage electrical appliances, the insulation of high-voltage electrical appliances has attracted more and more attention. epoxy resin is the most common in current high-voltage electrical insulation systems. its application is of great significance to the safety of the entire power system. with the continuous increase of voltage, the requirements for electrical insulation systems have become more and more stringent. the development of large-capacity power generation technology has promoted the increase of power voltage. it has also continuously made progress and optimization of insulation materials.

伴随着科学技术发展和化学工业的日益进步,环氧树脂也越来越复杂,其构成和组成方式日益繁琐。按照其组成方式我们就可以将环氧树脂分为缩水甘油酯类、缩水甘油醚类、脂肪族环氧化合物等。按照当前的工作状态以及工作方法,我们可以将环氧树脂分为液态环氧树脂和固态环氧树脂两种。

with the development of science and technology as well as the increasing progress of chemical industry, epoxy resin is becoming more and more complex. its composition and combination methods are becoming more and more complicated. according to their composition we can divide epoxy resins into glycidyl esters, glycidyl ethers and aliphatic epoxy compounds. according to the current working status and working methods, we can divide epoxy resins into liquid epoxy resins and solid epoxy resins.

由于环氧树脂的绝缘性能高、结构强度大和密封性能好等许多独特的优点,已在高低压电器、电机和电子元器件的绝缘及封装上得到广泛应用。主要用于电器、电机绝缘封装件的浇注,如电磁铁、接触器线圈、互感器、干式变压器等高低压电器的整体全密封绝缘封装件的制造。特别在电器工业中得到了快速发展,从常压浇注、真空浇注已发展到自动压力凝胶成型。

due to its many unique advantages, such as high insulation performance, high structural strength and good sealing performance, epoxy resin has been widely used in the insulation and packaging of high and low voltage electrical appliances, motors and electronic components. it is mainly used for casting of electrical equipment and motor insulation packaging, including the manufacturing of integrally sealed insulating packages for high and low voltage electrical appliances such as electromagnets, contactor coils, mutual inductors and dry-type transformers. it has developed rapidly in the electrical industry from normal pressure casting and vacuum casting to automatic pressure gel forming.

南通新纳希新材料有限公司可以提供三款脂环族缩水甘油酯类环氧树脂,牌号分别为s-182、s-184和s-186。本文将重点介绍s-182和s-184在户外高压电器绝缘中的具体应用分析。新纳希环氧树脂凭借着优异的机械、热以及介电性能,广泛用于户外绝缘的电气设备。

nantong synasia new material co., ltd. can provide three different types of cycloaliphatic glycidyl ester epoxy resins, including s-182, s-184 and s-186. in this post, we will introduce the specific application analysis of s-182 and s-184 in outdoor high-voltage electrical insulation. due to excellent mechanical, thermal and dielectric properties, synasia epoxy resins are widely used for insulation in outdoor electrical equipment.

01. 新纳希产品介绍/synasia product introduction

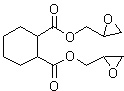

syna s-182

cas no. 21544-03-6

化学品名:四氢邻苯二甲酸二缩水甘油酯

chemical name: tetrahydrophthalic acid diglycidyl ester

s-182作为一款低粘度基础树脂,耐低温性能极佳。可以选用酸酐和胺类作为固化剂,用于绝缘材料浇筑体。

as a low-viscosity base resin, s-182 is best known for its excellent resistance to low temperature. this product can be cured with either amines or anhydrides. itis suitable for insulating materials in casting bodies.

对于高压电器来说,环氧浇注绝缘体的出现不仅会使高压电器介电性能、机械强度等得到提高,而且还能使电子器件体积减少,质量减轻等。在生产环氧浇注绝缘体时,不仅需要保证其工艺性,比如流动性、浇注温度、凝胶化速度、固化速度等等,而且也要保证胶在固化过程中有良好的裂开性和较高的耐热性。这就需要在生产过程中,化学反应放热量及其体积收缩率要小,热膨胀系数与嵌入固体件的热膨胀系数要接近,固化物要有较高的机械强度等。

the appearance of epoxy cast insulators will not only improve the dielectric properties and mechanical strength of high-voltage electrical appliances, but also reduce the volume and quality of electronic devices. in the production of epoxy cast insulators, it is not only necessary to ensure its manufacturability, such as fluidity, casting temperature, gelation speed, curing speed, etc., but also to ensure that the glue has good cracking and high resistance during the curing process. this requires that in the production process, the heat of chemical reaction and its volume shrinkage should be small. its thermal expansion coefficient should be close to that of the embedded solid part and the cured product should have higher mechanical strength.

syna s-184

cas no. 5493-45-8

化学品名:六氢邻苯二甲酸二缩水甘油酯

chemical name: hexahydrophthalic acid diglycidyl ester

s-184 是基于六氢邻苯二甲酸酐的低粘度双官能脂环族缩水甘油酯环氧树脂。它可以用胺或酸酐固化。由于它是完全脂肪族的,因此该产品非常适合在户外使用时承受阳光和紫外线照射。用加速酸酐固化剂固化时,可达到110℃以上的玻璃化转变温度。

s-184 is low-viscosity difunctional cycloaliphatic glycidyl ester epoxy resin based on hexahydrophthallic anhydride. it can be cured with either amines or anhydrides. because it is fully aliphatic, this product is well suited to withstand sun and uv exposure in outdoor use. when cured with accelerated anhydride curing agents, glass transition temperature in excess of 110℃ can be attained.

s-184主要用于为中高压设计的户外电气绝缘应用。由于它是不含双酚a的环氧树脂,因此该产品非常适合用于不黄变的涂料、电绝缘部件,特别是铸造体中的绝缘材料,例如变压器填料。

s-184 is used mostly in applications for outdoor electrical insulation designed for medium and high voltage. because it is bisphenol-a free epoxy resin, this product is excellent for non-yellowing coatings, electrical insulating components, especially the insulating materials in casting bodies, e.g., transformer fillers.

就当今的环氧树脂的应用实践进行分析,环氧树脂在应用的过程中不仅具备着粘结性良好、固化过程较为科学、耐热性与耐久性高的特点,同时其抗腐蚀性、抗机械强度也较高,能够满足各种不同高压配线施工要求。

based on the application analysis of today’s epoxy resin, epoxy resin not only has the characteristics of good adhesion, scientific curing process, good heat resistance and high durability, but it also provides excellent resistance to corrosion and mechanical strength. it can meet various high-voltage wiring requirements in construction.

对于绝大部分高压电器来说,通常采用露天的方式进行运作。所以耐气候变化的环氧绝缘漆的研发势在必行。s-184因其耐候性极佳,特别适合户外高压电器绝缘材料中的应用。

most high-voltage electrical appliances usually operate in the open air. therefore, the research and development of weather-resistant epoxy insulating paint is imperative. s-184 is especially suitable for the application of outdoor high-voltage electrical insulation materials due to its excellent weatherability.

随着我国智能电网体系的建设以及对输变电的安全与可靠性要求的不断提高,作为输配电重要设备的开关、绝缘子、变压器及互感器等户外高压电器产品,其绝缘的无油化、无瓷化已成为电力部门迫切需要解决的问题。目前,以脂环族环氧树脂为代表的户外环氧树脂浇注料已逐步代替硅橡胶,在10~110 kv电压等级绝缘中占主导地位。

with the construction of china's smart grid system and the continuously increased safety and reliability requirements of power transmission and transformation, outdoor high-voltage electrical products such as switches, insulators, transformers, mutual inductors and so on, which are important equipment for transmission and distribution. oil-free and porcelain-free insulation has become an urgent issue in the power sector. at present, outdoor epoxy resin castables especially cycloaliphatic epoxy resins have gradually replaced silicone rubber. they have taken a leading role in the insulation of voltage levels of 10 to 110 kv.

02. 环氧树脂浇注工艺/epoxy resin casting technology

环氧树脂浇注的工艺方法,从不同的工艺条件去理解有不同的区分方法。从物料进入模具的方式来区分可分为浇注和压注;浇注指物料自流进入模具。它又分常压浇注和真空浇注;压注指物料在外界压力下进入模具,并且为了强制补缩 , 在物料固化过程中,仍保持着一定的外压,它由过去的简单加压凝胶法发展成现在成熟的自动压力凝胶法。从物料固化温度来区分,可分为常温浇注法和高温浇注法。

epoxy resin casting method varies with different technical conditions. according to the way the material enters the mold, it can be divided into casting and injection molding. casting refers to the self-flowing of the material into the mold. it is divided into normal pressure casting and vacuum casting. injection molding means that the material enters the mold under external pressure, and in order to force the feeding, the material still maintains a certain external pressure during the curing process. it has developed from the simple pressure gel method in the past to the mature automatic pressure gel method. according to the solidification temperature of the material, it can be divided into normal temperature casting method and high temperature casting method.

从物料固化的速度来区分可分为普通固化法和快速固化法。现代浇注工艺中,应用比较成熟的浇注工艺方法主要是真空浇注法和自动压力凝胶法。环氧树脂浇注是将环氧树脂、固化剂和其他配合料浇注到设定的模具内,由热塑性流体交联固化成热固性制品的过程。目前常用的方法有真空浇注法、常压浇注法以及环氧树脂全密封的新工艺、新技术。

according to the curing speed of the material, it can be divided into ordinary curing method and fast curing method. in modern casting technology, mature casting methods mainly include vacuum casting method and automatic pressure gel method. epoxy resin casting is the process of casting epoxy resin, curing agent and other materials into a set mold, and then cross-linking and curing by a thermoplastic fluid into a thermoset product. at present, commonly used methods include vacuum casting method, normal pressure casting method and innovative epoxy resin full sealing technology.

03. 环氧树脂发展趋势/epoxy resin development trend

环氧树脂电子电器封装及绝缘材料的发展方向主要是:提高材料的耐热性、介电性和阻燃性,降低吸水率、收缩率和内应力。改进的主要途径是:合成新型环氧树脂和固化剂;原材料的高纯度化;环氧树脂的改性,比如增韧、增柔、填充、增强、共混等;开发无溴阻燃体系;改进成型工艺方法、设备和技术。随着半导体技术的飞速发展,对封装材料的要求也越来越高,普通环氧树脂已不能完全满足技术要求。

the development direction of epoxy resin based electrical encapsulation and insulation materials is mainly to improve the heat resistance, dielectricity and flame retardancy of materials, and reduce water absorption, shrinkage rate and internal stress. the main ways of improvement include: synthesis of new epoxy resins and curing agents, higher purity of raw materials, modification of epoxy resins, such as toughening, softening, filling, strengthening, blending, etc., development of bromine-free flame retardant systems as well as the improvement of molding methods, equipment and technology. with the rapid development of semiconductor technology, the requirements for packaging materials are getting higher and higher. ordinary epoxy resins can no longer fully meet the technical requirements.

目前国外对环氧树脂技术改进主要集中在:

for the improvement of epoxy resin technology, overseas companies mainly focus on:

开发低粘度或熔融粘度低的二官能团型的环氧树脂,通过填充高含量无机填充剂,大幅度降低封装器件的内应力,减少钝化开裂、配线松动和导线断裂等不良缺陷。

development of low-viscosity or low-melt-viscosity difunctional epoxy resins at present. with the use of high-content inorganic fillers, the internal stress of the packaged devices is greatly reduced, which helps minimize undesirable defects such as passivation cracking, loose wire, wire break, etc.

开发多官能团型的环氧树脂,同时在环氧树脂中导入耐热和耐湿结构的化合物,使封装器件既具有高耐热性,又具有低吸水率和低的内应力。

development of multifunctional epoxy resins and at the same time introduce heat-resistant and moisture-resistant structural compounds into the epoxy resin, so that the packaged device can offer high heat resistance, low water absorption and low internal stress.

上一条: how to choose the photoinitiators? 下一条: how much do you know about composites