利来国际w66首页 > 新闻中心 > 公司新闻

一分钟带你了解光固化涂料

|

更新日期: 2021-5-17 |

光固化涂料主要指在紫外光照射下迅速交联固化的一类新型涂料,通常指从液体树脂变成固态干膜的过程。因其高效涂装固化、低能耗和环境友好特征,已为世界涂料行业认可,近年来发展迅速。

uv cured coating mainly refers to a new type of coating which is quickly cross-linked and cured under ultraviolet (uv) irradiation. it usually refers to the process of changing from a liquid resin to a solid dry film. because of its high-efficiency curing process, low energy consumption and environment-friendly characteristic, uv cured coating has been globally recognized by the coating industry. it has developed rapidly in recent years.

part

1

历史/history

★20世纪60年代由bayer公司成功商业化光固化涂料。

uv cured coating was put into commercial production by bayer in the 1960s.

★2000年全球仅用于家具等木器涂装的光固化涂料已超过2.2万吨。

over 22,000 tons uv cured coating was globally used on wood only for furniture in 2000.

★2010年用于包装领域的光固化涂料增至5.3万吨。

up to 53,000 tons uv cured coatings was used in packaging industry in 2010.

★至今大量应用于纸张、塑料、金属、玻璃、陶瓷等多种基材。

till date, a huge number of uv cured coatings have been applied on paper, plastic, metal, glass, ceramic and many other substrates.

part

2

波长/wavelength

在一般光化学研究和光固化应用中有实际意义的是中紫外和近紫外区的紫外光,通常又划分为以下三个波段: uv a, uv b 和 uv c。光固化体系常用uv a (315~400nm) 和 uv b (280~315nm),集成电路制作的光刻技术常用uv c (200~280nm)。

in general photochemical research and uv curing applications, uv light is usually divided into the following three bands during the mid-ultraviolet and near-ultraviolet regions, including uv a, uv b and uv c. among them, uv a (315~400nm) and uv b (280~315nm) are commonly used in uv cure system. uv c (200~280nm) is usually applied in lithography technology for integrated circuit production.

part

3

应用/application

光固化涂料/uv cured coating

光固化油墨/uv cured ink

应用于包装装潢、印刷、电子 (抗蚀油墨、阻焊油墨、标记油墨) 等。

used in packaging, printing, electronics (anti-corrosion ink, solder mask ink, marking ink), etc.

光固化胶黏剂/uv cured adhesive

分为结构胶、密封胶、层合胶、压敏胶等。应用于光学镜头装配、水晶工艺品、微电子装配、金属和塑料支架接合、一次性医疗器械、液晶显示屏装配、玻璃器皿粘接等。

divided into structural adhesives, sealants, laminating adhesives, pressure-sensitive adhesives, etc. used in optical lens assembly, crystal crafts, microelectronic assembly, metal and plastic bracket bonding, disposable medical equipment, lcd display assembly, glassware bonding, etc.

光刻胶/photoresist

用于光刻术的感光材料。

used for photolithography in photosensitive materials.三维激光成型/3d laser forming

20世纪80年代末发展起来的快速成型技术,利用激光引发感光树脂的聚合,要求感光树脂低粘度、高固化速度、低收缩、低溶胀、层间黏附相容性好、光敏感度高等。

the rapid prototyping technology was developed in the late 1980s. it uses laser to initiate the polymerization of photosensitive resins. the photosensitive resin must possess low viscosity, high curing speed, low shrinkage, low swelling, good interlayer adhesion compatibility and high photosensitivity.

part

4

组成/composition

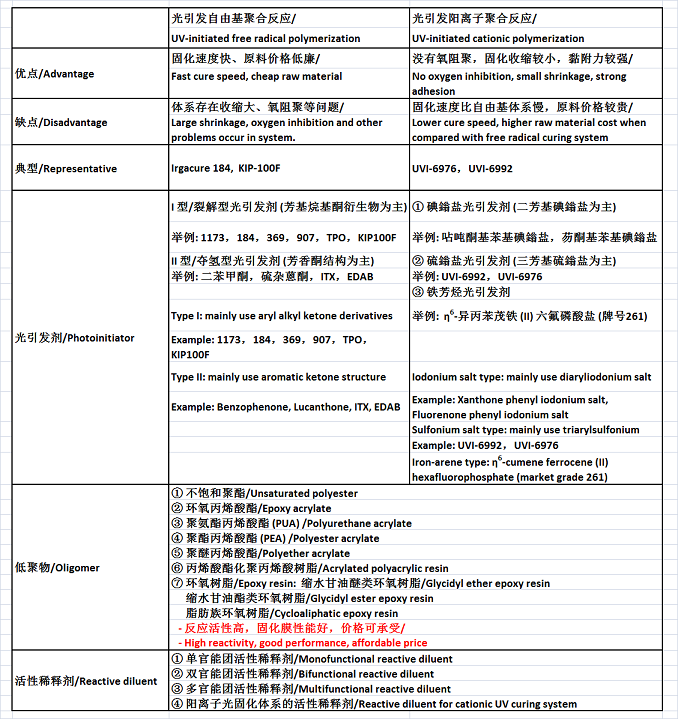

自由基型光引发剂 (free radical photoinitiator) /

阳离子型光引发剂 (cationic photoinitiator)

低聚物/oligomer

活性稀释剂/reactive diluent

各种助剂/various additives

感光组分包括低聚物和活性稀释剂,占整个配方的90%以上。

photosensitive part includes oligomer and reactive diluent, which accounts for over 90% of the entire formula.

光固化涂料常用组分/

common components of uv cured coatings

南通新纳希新材料有限公司已具备10余年脂环族环氧树脂生产经验,生产能力稳定,产品质量可靠,致力于为客户提供优质服务,欢迎海内外客户来电垂询!

nantong synasia new material co., ltd. has more than 10 years of experience in the production of cycloaliphatic epoxy resins. we are committed to providing customers with stable production capacity, reliable product quality and considerate service. welcome customers at home and abroad to contact us!

上一条: 脂环族环氧树脂在uv阳离子光固化中的应用(二) 下一条: 一文读懂碳纤维缠绕技术